Bambu ASA

Bambu ASA is a highly durable material that offers exceptional UV, weather, mechanical, and thermal resistance. Its unique combination of properties makes it an ideal material for printing outdoor models (plant signs, mailboxes, wind vanes, etc.) and structural parts that require long-term exposure to challenging outdoor conditions.

Extraordinary Weather & UV Resistance

Bambu ASA offers extraordinary UV, oxidation, and aging resistance, providing effective protection against breakage and color degradation when used outdoors for long-term purposes.

Tough and Durable

Suitable for outdoor applications and regular structural requirements due to its toughness and high impact strength.

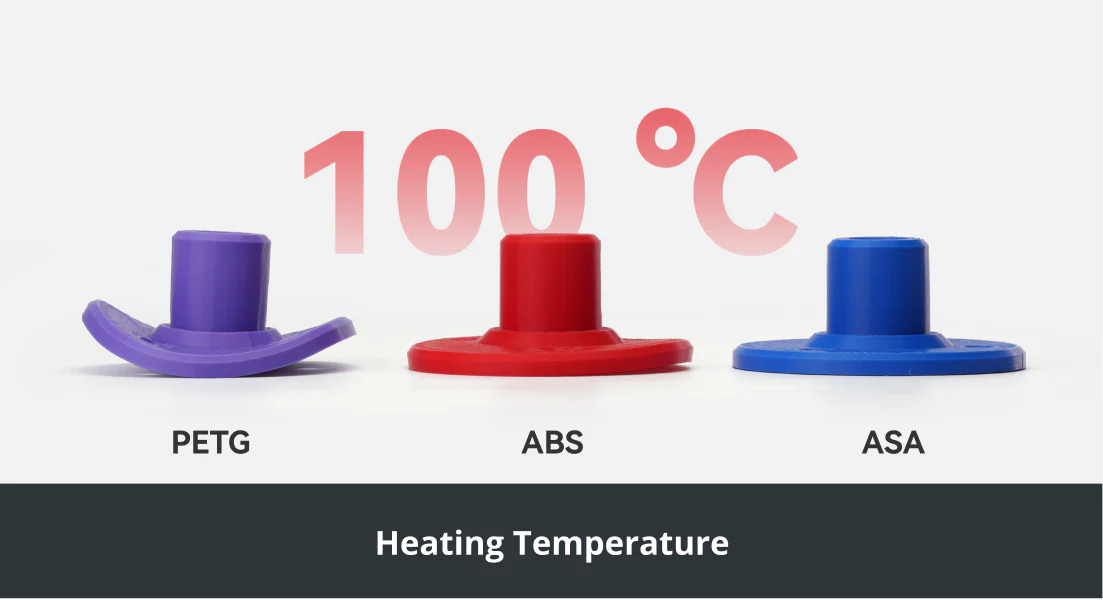

Better Temperature Resistance

Compared to normal PETG or ABS, Bambu ASA can remain in shape even at a temperature of 100°C.

Frequently Asked Questions

1. What's the difference between ABS and ASA?

ABS - acrylonitrile - butadiene - styrene

ASA - acrylonitrile - styrene - acrylate

ASA is a modified version of ABS that contains an additional acrylate component, which improves its weather adaptability and UV resistance.

ASA retains the impact resistance and processability of ABS while providing better resistance to fading, yellowing, and degradation from sunlight exposure. Both of them may release pungent and unpleasant odors during printing, but the pungent odor of ASA is notably lighter than ABS.

2. What is the difference applications between ABS and ASA?

ASA is ideal for outdoor applications, such as automotive exterior parts, signage, and outdoor equipment, thanks to its enhanced weather resistance and color stability. ABS is a versatile material with excellent mechanical properties that is commonly used for indoor applications.

3. What are the similarities between ABS and ASA?

In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with almost the same levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and the same warping tendency and enclosed printer requirement when printing large-size and/or high infill density models.