Fay and I visited a friend's house yesterday to dive into assembling the new OnefinityCNC. I was curious to understand what the hype around the Onefinity brand was all about. It was such a cool day to see someone's design come to life.

The clear attention to detail begins from the moment you begin putting this thing together. We assembled it based on our instincts, and the majority of the construction was straightforward and apparent.

As we assembled all its components, it became clear how this machine empowers creators to undertake commercial projects at a prosumer-friendly price point.

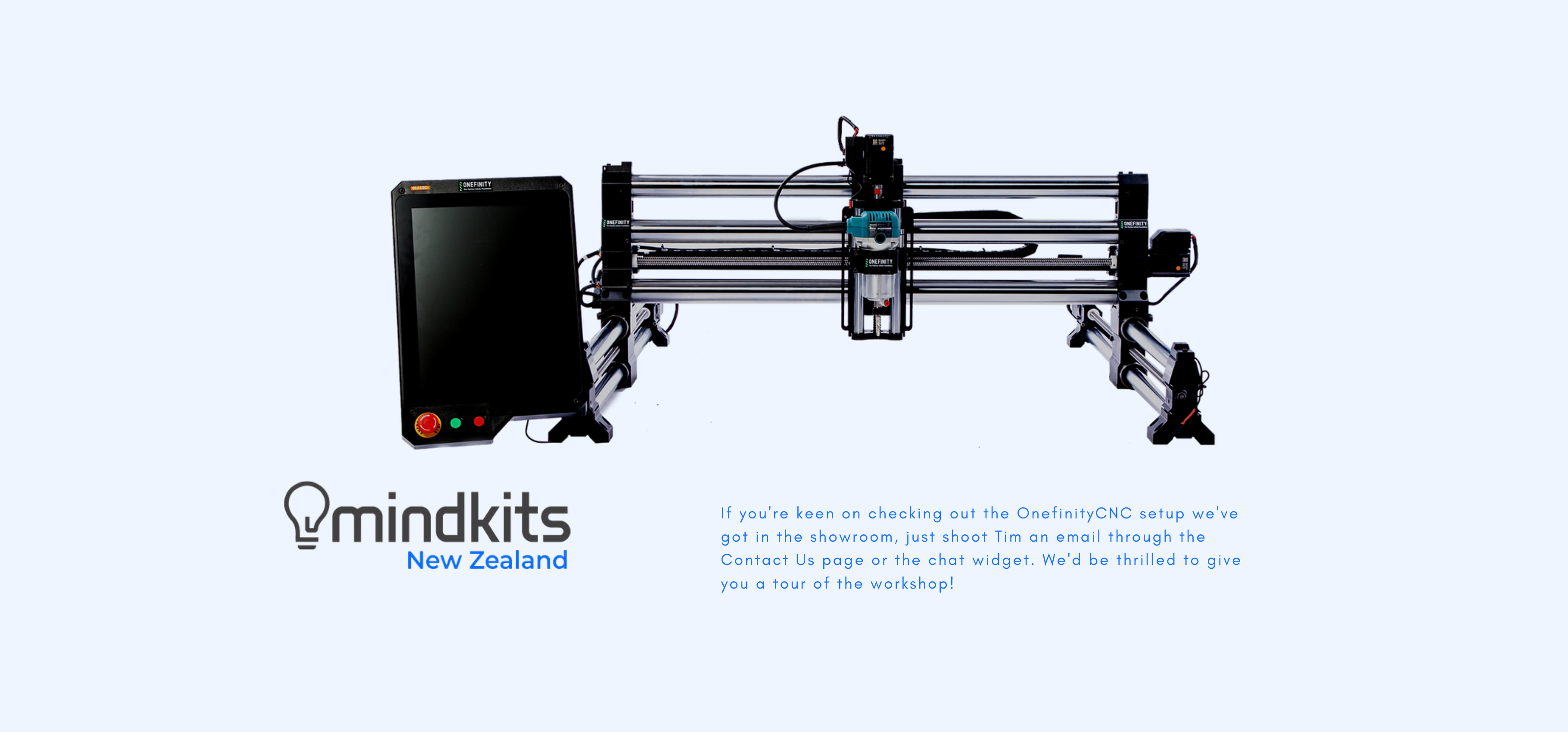

This bad boy is way more impressive in person. The size and quality of the parts don't translate well in the product pictures. This substantial and robust device proved to be quite impressive. What struck me was the thickness of the beams utilised for the Y axis. They were as thick as my arm! There's a certain satisfaction in the soft, singular, deep clunk sound as two flawlessly machined metal surfaces meet with such an impeccable fit that they seem as though they were separated at birth and are now being reunited. As we assembled all its components, it became clear how this machine empowers creators to undertake commercial projects at a prosumer-friendly price point.

We chose the fixed-leg table for its intended permanent setup, but we also had the flexibility of foldable legs. These foldable legs provide the option to easily roll the table away under another surface or store it conveniently.

The display mounting kit felt a little flimsy, so I'll likely 3d print something to replace it eventually. Bonus points for the well-labelled cables, ready to plug into the obvious home where it belonged. Firing up the CNC was a breeze. we quickly upgraded to the new version that doesn't rely on the browser. Now, onto the next milestone - the first cut!