DNAiTECH is a biotechnology company based in Marlborough, New Zealand developing technologies for point-of-care diagnostics.

The technology they are creating allows testing for disease-causing agents and organisms to be done at a primary care level, where it is required. For instance, for biomedical applications, it could be a primary care clinic or field hospital. For environmental or agricultural applications it means in the field. The advantage of point of care is that there is no delay in waiting for the results of tests to come back from testing laboratories. This means treatment and isolation of the disease can be immediate.

Pretty amazing stuff if you ask me!

The Problem - Prototyping, Research and Development is Expensive!

It is important that DNAiTECH are able to make prototype devices and test them for functionality. The complex devices being developed cost hundreds of thousands of dollars to prototype externally and the time to market is considerable when multiple revisions need to be made.

To make sure they are competitive in their industry it is important for DNAiTECH to be able to test their iterations quickly.

The Solution - Laser Cutting Technology Speeds Up Prototyping

Laser cutting allows DNAiTECH to complete all their prototypes in-house and quickly make changes, all while saving significant time and money. They are now close to the commercial release of their first product - a separation device that prepares samples from large microorganisms down to viruses - very exciting stuff from a New Zealand-based company.

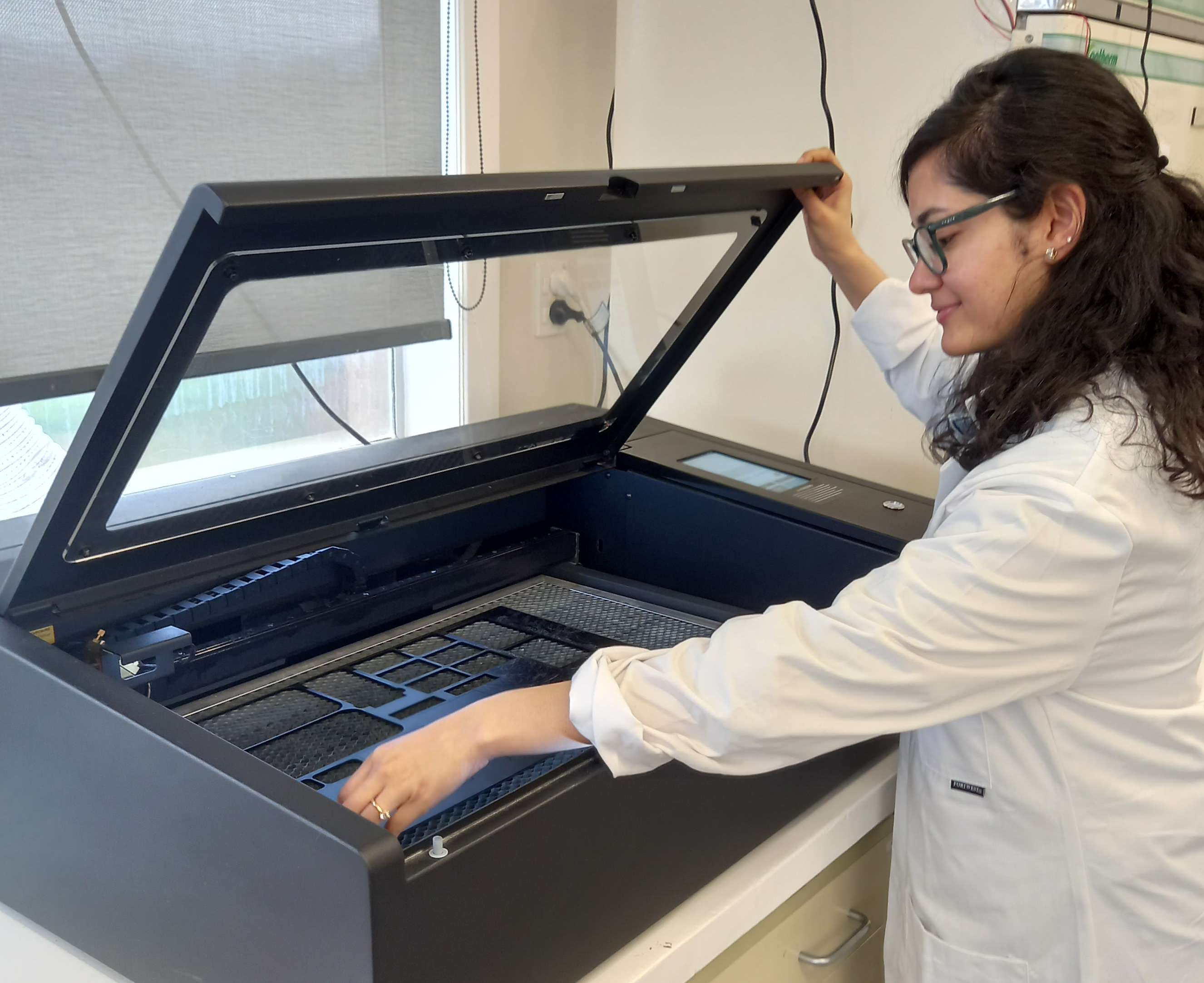

All prototypes were made using a Beambox Pro Laser Cutter. A versatile laser cutter that can cut through and engrave on a wide range of materials.

Competitive Advantage

The easy-to-use laser cutting technology allows DNAiTECH to get its devices out into the marketplace faster than traditional prototyping allows, as everything they need to test their designs is right there in the lab.

“The laser system has been incredible for our prototype development. We can manufacture parts rapidly in acrylic, assemble the parts by glueing them together, and then make incremental changes as required. It's used every day, fairly continuously. The program is moving fast because we can make a design change and within 10 minutes have the new parts for assembly and testing. We could not have done this without the laser technology.

I would highly recommend MindKits as a New Zealand supplier, they were easy to deal with and upon ordering we had our laser within a week or so. Great service”

Murray Broom, DNAiTECH