Bambu Lab A1 3D Printer COMBO with 4 Colour Printing

(Placeholder Product Listing. Please expect changes and refinements)

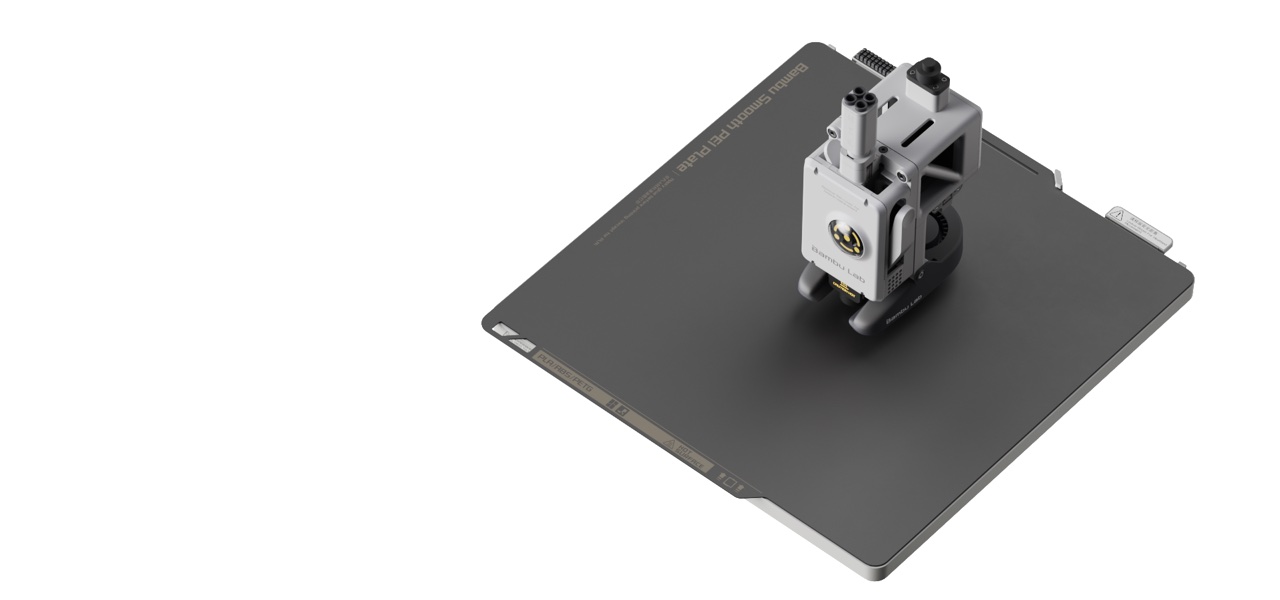

Multicolour Printing For Everyone

Product Features

- AMS lite with, up to 4-color printing.

- Pre-assembled, pre-tuned, pre-squared, plug-n-play.

- Active Flow Rate Compensation (Auto-calibrated Pressure Advance), precise extrusion at every corner.

- Active Motor Noise Cancellation, under 48dB in silent mode.

- Filament tangle and runout monitoring, all-rounded ensuring filament feed.

- Full-metal linear rails and rigid frame, robust quality from day one to beyond.

Goodbye to Tedious Manual Calibration And Tuning

A1 handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

Goodbye to Tedious Manual Calibration And Tuning

A1 handles various calibrations all by itself. It meticulously calibrates the Z-offset, bed-level, vibration resonance and nozzle pressure for EVERY print job, automatically.

No More "Paper Method"

A1 probes the bed with the nozzle to measure the absolute Z-offset. No need to stick a paper as reference.

Auto Tune Both X & Y Resonance Before Every Print

A1 has sensors in toolhead and heatbed. One of the very first bed-slinger printers to run auto resonance calibration on both X & Y axes.

Fully Automated PA (Pressure Advanced) Calibration

First of its kind, A1 runs the nozzle pressure based flow dynamics calibration algorithm. No need to draw any pattern or get any manual pick & match involved, A1 handles Pressure Advanced calibration automatically.

Auto Monitoring And Adjusting The Belts

A1 can check the belt tension automatically through the vibration frequency calibration. If the belt tension is loose the HMS system will notify you to adjust the auto belt tensioner.

Load/Unload Filament With One Touch

No manual setting involved, A1 fully automated the filament load/unload process.

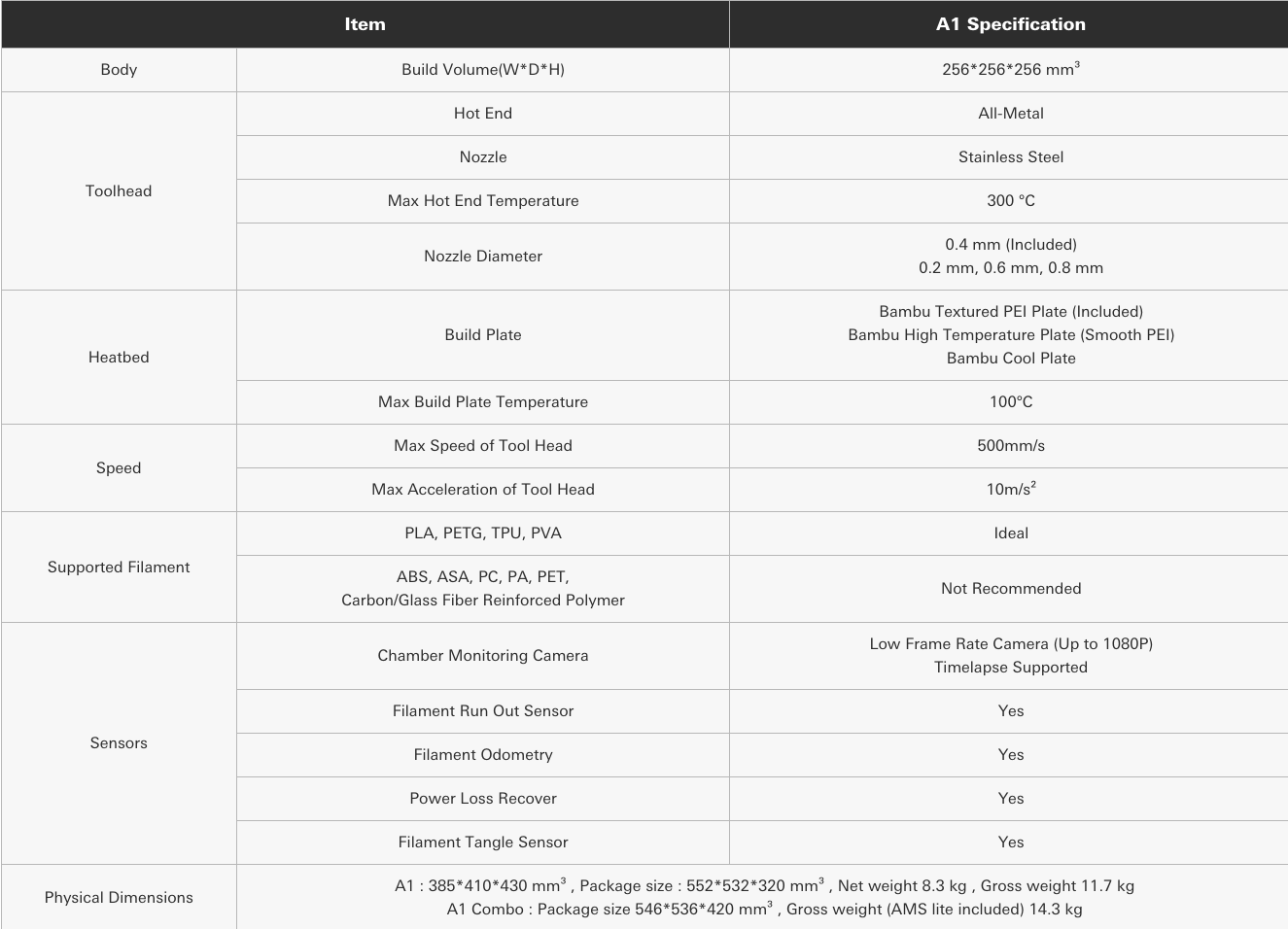

Swift Maintenance

Quick Swap Nozzles

All-new quick swap hotend design, the hotend pops in and out with just 1 clip.

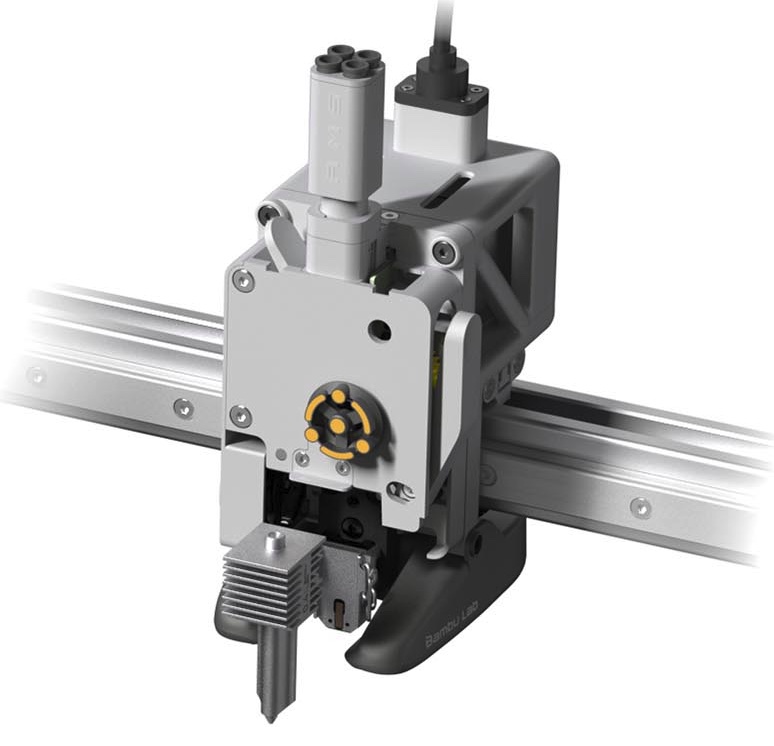

Active Flow Rate Compensation

Print Smooth At Every Corner, Always

The A1 revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency eddy current sensor to measure the pressure in the nozzle. Our algorithm actively compensates the flow rate according to the readings to extrude with accuracy.

High-speed Precision

Bed Slinger with CoreXY Speed And Quality

Full-metal Rails, Rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and above all, an advanced motion control system that utilizes these features to print a 14-minute benchy with quality and following all the speed benchy rules straight out of the box without using specialized filaments.

Intuitive UI

As Easy As Your Smart Phone

A1 now has a simplified touchscreen UI system that walks you through all the hurdles. You don't have to be a 3D printing expert to use the A1.