Bambu PETG Basic

Known for impact and water resistance, high flexibility, strong layer adhesion, Bambu PETG Basic is ideal for printing tools (vises, tensioners, bag clips), toys (frisbees, boomerangs), water containers (bottles, watering cans), and outdoor items (planter pots, bottle cages) that require long-term exposure and withstanding impacts.

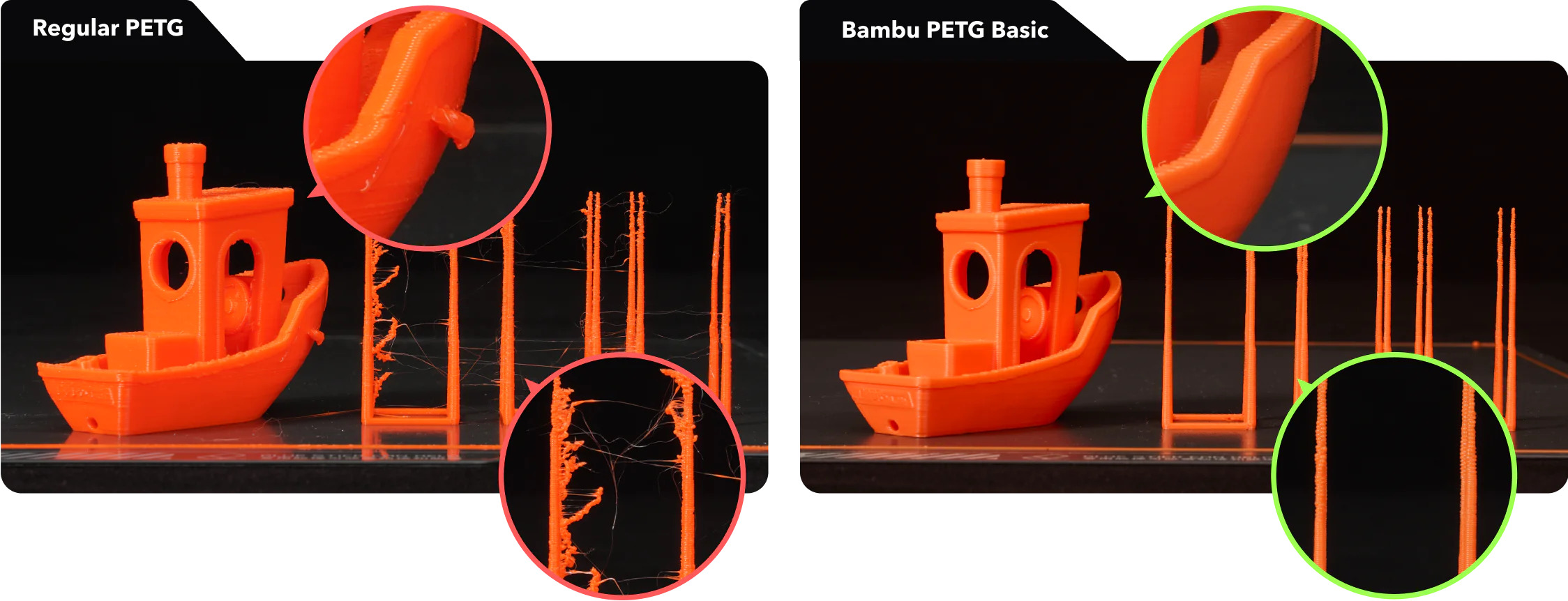

Less oozing, stringing and clumping

Improved with a modified formula, Bambu PETG Basic reduces clumping, oozing, and stringing issues during printing.

Excellent Light transmittance

With exceptional light transmittance, Bambu PETG Basic can achieve translucent or even transparent looks with particular printing settings.

*Please note that the transparency of the prints may vary depending on factors such as size and structure, as well as printing parameters (including speed, nozzle temperature, and infill density). Learn more about Printing tips for transparent PETG.

Experience superior toughness and impact resistance

An upgrade from regular PLA materials for high flexibility and excellent impact resistance.

Print outdoor models with ease

The waterproof and weather-resistant solution for your garden decor and furniture needs.