PolyMideTM is a family of Nylon/polyamide based filaments. Produced with Polymaker’s Warp-FreeTM technology, PolyMideTM filaments deliver engineering properties intrinsic to Nylon and ease of printing. PolyMideTM PA12-CF is a carbon fiber reinforced PA12 (Nylon12) filament featuring 10% chopped carbon fibers by weight. Thanks to the low moisture sensitivity of PA12, this product features outstanding mechanical and thermal properties even after the moisture conditioning process. Combined with its ease of print with Warp- FreeTM technology, this product is ideal to create manufacturing tools.

Although Nylon 12 is less sensitive to moisture, we highly recommend to use a wear resistant nozzle to print with and to keep it at dry conditions (relative humidity of 15% or less) at all times to maintain the best printing results.

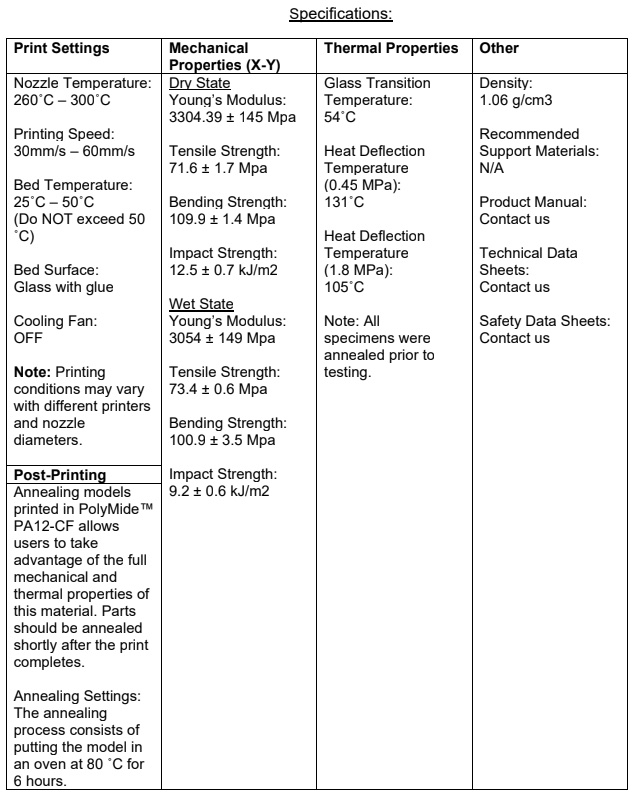

Excellent Heat Resistance - Featuring a heat deflection temperature of 131°C, this material lends itself to operate in demanding environments where heat and stress are critical design factors.

Outstanding Layer Adhesion - All other brands of fiber reinforced material show a decrease in z-axis layer adhesion when compared with their non-fiber reinforced Nylons, producing a part that is only stronger on the X-Y axis but detrimental to the Z axis. Polymakers Fiber AdhesionTM technology improves the layer adhesion of fiber reinforced materials, by optimizing the surface chemistry of the fibers to achieve better dispersion and bonding to the matrix. The implementation of this technology in PolyMideTM PA12-CF not only solves this problem but actually increases Z axis tensile strength creating more isotropic parts that are strong in every direction.

Warp-FreeTM - Warp-FreeTM technology enables the production of Nylon-based filaments that can be 3D printed with excellent dimensional stability and near-zero warpage. This is achieved by the fine control of microstructure and crystallization behaviour of Nylon, which enables the material to fully release the internal stress before solidification. The Warp-FreeTM technology in PolyMideTM PA12-CF is designed to work best with minimal bed temperatures.

Surface Finish & Printability – PolyMideTM PA12-CF renders prototypes, manufacturing jigs and functional parts with an excellent surface finish due to better fluidity of PolyMideTM PA12-CF and less fiber content compared to PolyMideTM PA6- CF. Unlike many other Nylon filaments, PolyMideTM PA12-CF is extremely easy to work with, exhibiting excellent dimensional stability. It is compatible with most filament-based 3D printers capable of reaching 260°C nozzle temperature and no heated bed or chamber is required!

Uncompromised Quality - Polymakers leading quality control process and rigorous in-house testing ensure reliable printing and consistency across spools and batches.

What is “Dry” and “Wet” State: Nylon materials are hygroscopic and printed parts will naturally absorb moisture from the air and become moisture conditioned. Unless your 3D printed parts operate in particularly dry environments or are post processed with a moisture barrier, it’s generally assumed that all nylon printed parts will end up in their moisture conditioned properties in every-day use. PolyMideTM PA12-CF displays greater moisture stability when compared to common Nylon 6 filaments. This means that printed parts display

minimal change in mechanical properties from the dry state to the wet state to deliver more predictable results in the real world.

‐ This is a physical reaction which is completely reversible. The water molecules act as

a plasticizer inside the nylon and while it decreases tensile strength and stiffness, it

increases toughness and impact resistance.

‐ PA12 displays greater moisture stability in comparison to PA6, Less moisture absorption means that there is less change in mechanical properties from the dry state to the wet state.

‐ Once the material reaches equilibrium the part has become conditioned and will stop absorbing moisture. PA12 materials reach equilibrium at roughly 0.7% by weight in environments at 50% R.H (Moisture Conditioned State) and reach equilibrium at 1.5% by weight when saturated with water (Wet State).

‐ Dry state data represents the properties of PolyMideTM PA12-CF after printing and annealing the part. Wet state represents the properties of PolyMideTM PA12-CF after annealing and immersion in ambient temperature water for 3 days.

Storage: It is recommended to store PolyMideTM PA12-CF correctly to prevent moisture absorption which will lower the quality and the mechanical properties of the print. If the filament has absorbed moisture it can be dried at 75 ̊C for 6 hours in a convection oven.

We suggest an eVaccum bag for storage.

** Please note this is a specialist filament. So before purchasing please check with our support team. We want to make sure that you get the best out of your filament and there are a number of factors to consider before printing with this specialist filament**

Email us at support@mindkits.co.nz