Tim here, CEO and chief ninja of MindKits. What would happen if we gave our premium Innofil filament and our MindKits branded filament to a third party tester but didn't tell them which was which?

Would the Innofil come out on top? Would the MindKits filament print differently under controlled circumstances?

I gave three samples of filament to a third party tester and two of them were MindKits branded filament and one was premium Innofil filament. Thing is, I didn't tell them which one was which.

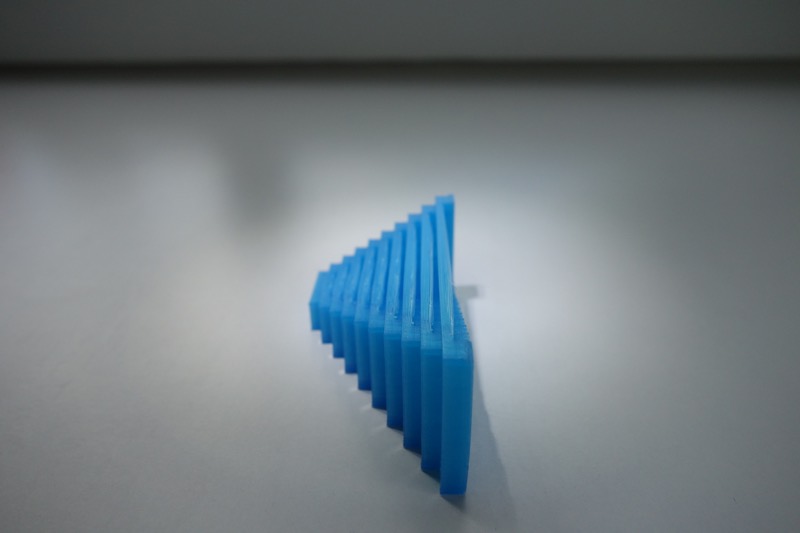

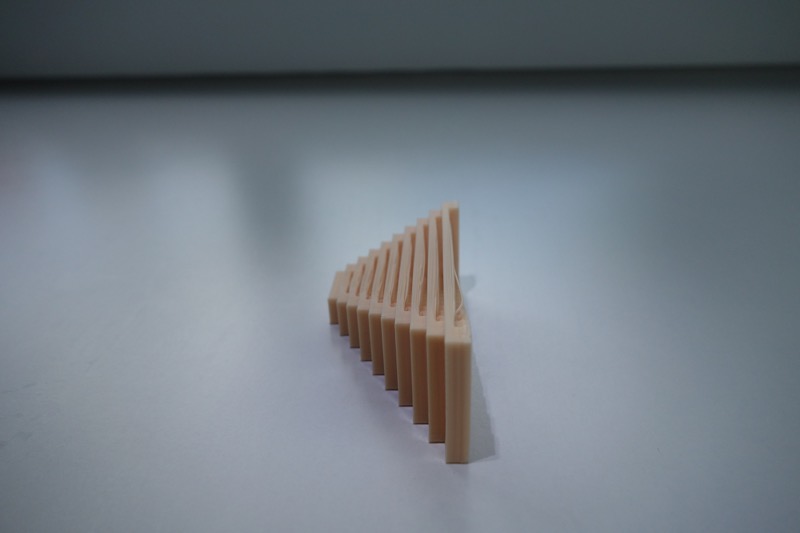

Blue and Skin - MindKits Filament

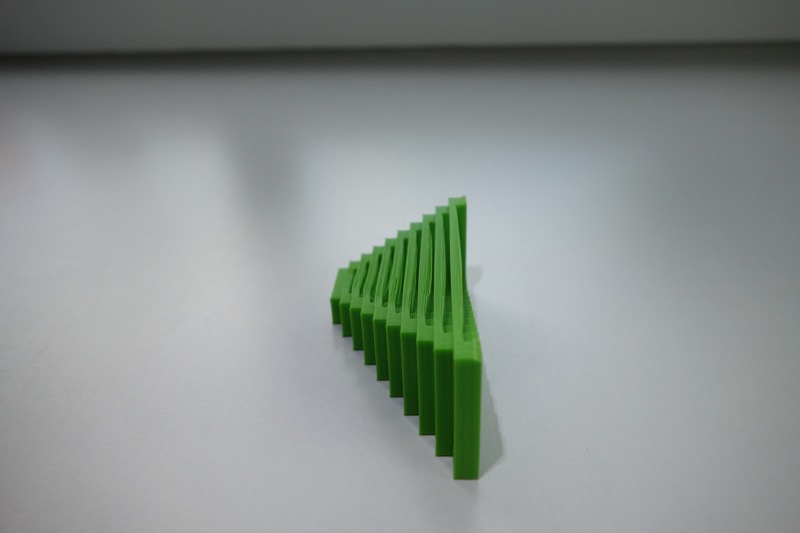

Green - Premium Innofil

Here's the results....

Test Results:

Diameter was tested across 300mm of filament and is a consistent 2.85mm on both the natural and green filaments with an average deviation of 0.02mm while the blue filament was a consistent 2.91mm with a similar deviation of 0.02-0.03mm.

The prints used the exact same settings (above) with the only changes being filament diameter.

The blue (Ed: This is MindKits Filament) being transparent is difficult to photograph and tends to hide minor imperfections well like most transparent and lighter colours, despite this it seemed print ever so slightly better than the green and natural (pink?) samples on the bridging test. The 50mm bridge had some drooping in the centre but was consistent without any stray strands.

The green (Ed: Innofil) strangely did just as well on the longer 50mm bridge but deteriorated a bit as the bridges got shorter towards the top, cooling was unchanged between prints.

The natural filament (Ed: MindKits Skin colour), printed last, gave similar results to the green sample except with a stray strand on the 50mm bridge. This was more than likely just an anomaly and may have occurred just as easily on the previous two prints.

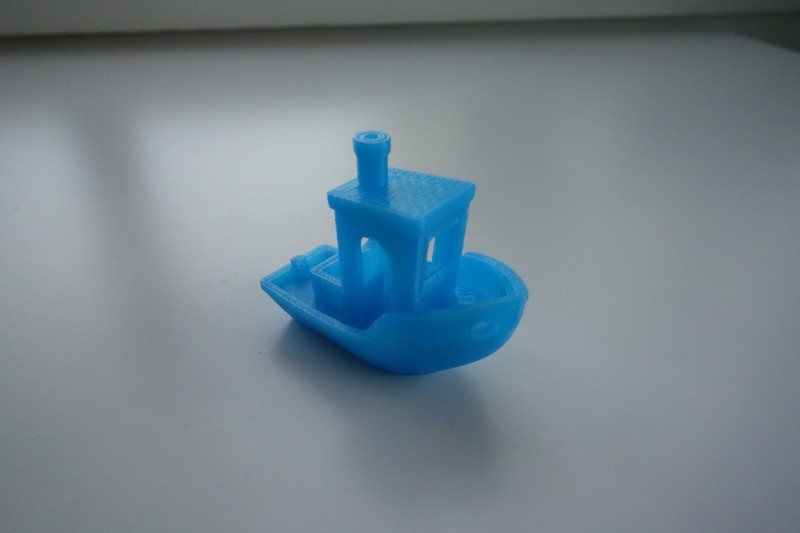

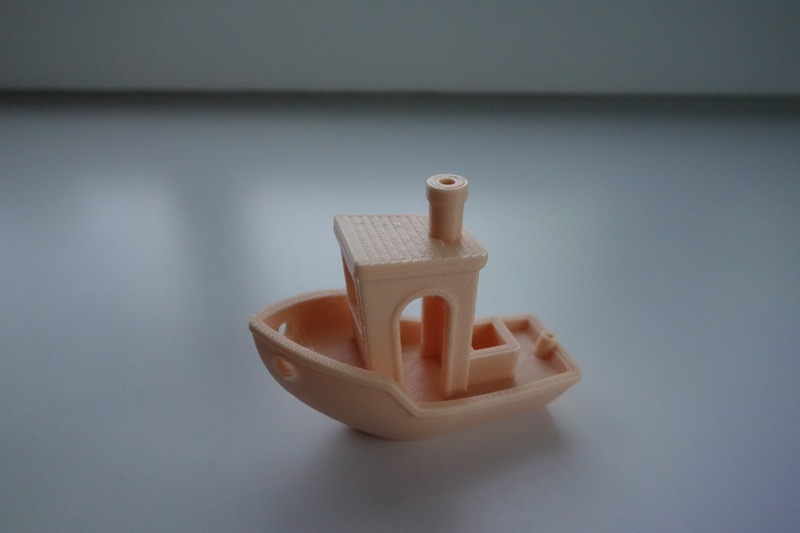

The 3D benchy prints printed really well on all 3 samples with no clean-up needed, I have left the tiny spider web stringing intact which was minimal anyway.

The blue had a couple of little blobs under the door frame but showed almost no drooping under the front or rear window. Lettering on the back was easily readable on all 3 prints with the Natural colour showing up better simply due to it’s contrasting colour.

Overhangs on the front of the print/boat were identical across each print with no drooping whatsoever with the only imperfections being some Z wobble still present from the printer.

The front left corner of the blue and green prints curled up slightly, likely due to the print orientation in relation to the part cooling and both had a couple of minor, almost negligible artefacts in the front portholes

The Natural colour had the cleanest portholes on the print and the flattest roof, the front left corner was flat and sharp.

Main Print settings:

Printer: Cartesian Home Built

Hotend: E3D V6

Extruder: E3D Titan rev 2

Slicer: Simplify 3d

Nozzle size: 0.4mm

Print temperature: 200c

Bed Temperature: 60c

Print Speed: 50mm/s

Layer height: 0.2mm

Extrusion width: 0.48mm

Retraction distance: 1mm

Extra restart Distance: 0mm

Retraction Vertical Lift: 0.2mm

Retraction Speed: 40mm/s

Coasting Distance: 0mm

Wipe Distance: 0mm

Top Solid Layers: 3

Bottom Solid Layers: 3

Outline/perimeter Shells: 3

Outline Under speed: 50%

Bridging Extrusion Multiplier: 80%

Bridging Speed Multiplier: 40%